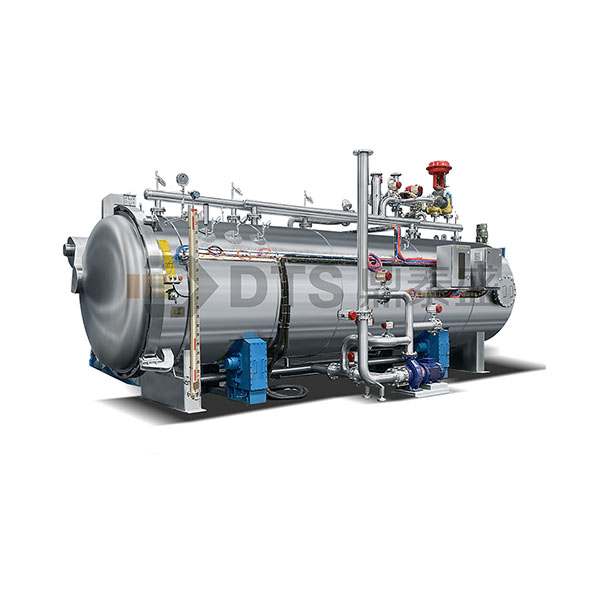

Hot New Products Steam Vertical Retort - Direct Steam Retort – Dingtaisheng

Hot New Products Steam Vertical Retort - Direct Steam Retort – Dingtaisheng Detail:

Description

The Saturated Steam Retort is the oldest method of in-container sterilization used by human. For tin can sterilization, it’s the simplest and most reliable type of retort. It is inherent in the process that all air be evacuated from the retort by flooding the vessel with steam and allowing the air to escape through vent valves.There is no overpressure during the sterilization phases of this process, since air is not permitted to enter the vessel at any time during any sterilization step. However, there may be air-overpressure applied during the cooling steps to prevent container deformation.

FDA and Chinese regulations have made detailed regulations on the design and operation of steam retort, so although they are not dominant in terms of energy consumption, they are still widely favored by many customers because of their wide application in many old canneries. On the premise of ensuring compliance with FDA and USDA requirements, DTS has made many optimizations in terms of automation and energy saving.

Advantage

Uniform heat distribution:

By removing the air in the retort vessel, the purpose of saturated steam sterilization is achieved. Therefore, in the end of come-up vent phase, the temperature in the vessel reaches a very uniform state.

Comply with FDA/USDA certification:

DTS has experienced thermal verification experts and is a member of IFTPS in the United States. It fully cooperates with FDA-approved third-party thermal verification agencies. The experience of many North American customers has made DTS familiar with FDA/USDA regulatory requirements and cutting-edge sterilization technology.

Simple and reliable:

Compared with other forms of sterilization, there is no other heating medium for the come-up and sterilization phase, so only the steam needs to be controlled to make the batch of products consistent. FDA has explained the design and operation of the steam retort in detail, and many old canneries have been using it, so customers know the working principle of this type of retort, making this type of retort easy for old users to accept.

Working principle

Load the full loaded basket into Retort, close the door. The retort door is locked through triple safety interlock to guarantee the safety. The door is mechanically locked throughout the whole process.

The sterilization process is automatically carried out according to the recipe of the input micro processing controller PLC.

In the beginning, steam is injected into the retort vessel through the steam spreader pipes, and air escape through vent valves. When both time and temperature conditions established in the process are met simultaneously, the process advance to come-up phase.In the whole come-up and sterilization phase, retort vessel is filled with saturated steam without any residual air in case of any uneven heat distribution and insufficient sterilization. The bleeders must be open for the entire vent, come-up, cooking step so that the steam can form convection to ensure the temperature uniformity.

Package type

Tin can

Applications

Beverages(vegetable protein, tea, coffee): tin can

Vegetable and fruit(mushroom, vegetables, beans): tin can

Meat, poultry: tin can

Fish, seafood: tin can

Babyfood: tin can

Ready to eat food, porridge: tin can

Pet food: tin can

Product detail pictures:

Related Product Guide:

No matter new customer or outdated client, We believe in extensive phrase and trusted relationship for Hot New Products Steam Vertical Retort - Direct Steam Retort – Dingtaisheng, The product will supply to all over the world, such as: Portugal, Malawi, Saudi Arabia, Our R&D department always designs with new fashion ideas so we could introduce up-to-date fashion styles every month. Our strict production management systems always ensure stable and high quality products. Our trade team provides timely and efficient services. If there are any interest and inquiry about our products, please contact us in time. We would like to establish a business relationship with your honored company.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.