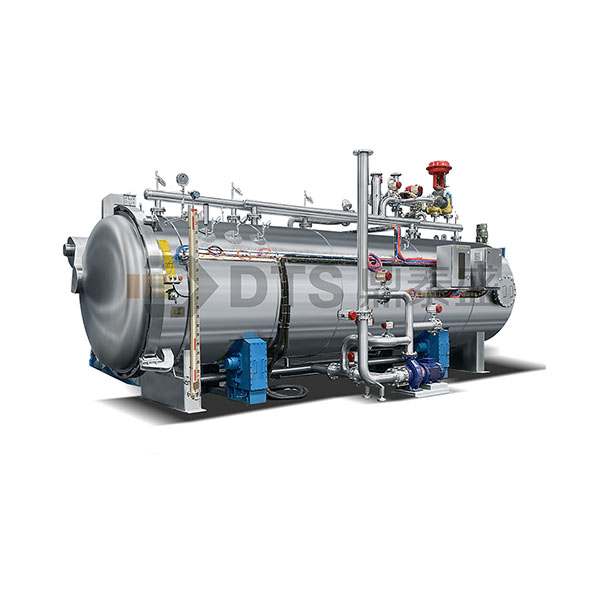

2020 High quality Steam Pilot Retort - Pilot Retort – Dingtaisheng

2020 High quality Steam Pilot Retort - Pilot Retort – Dingtaisheng Detail:

The working principle of the experimental retort

Put the product into the sterilization retort and close the door. The retort door is secured by triple safety interlocking. Throughout the whole process, the door is mechanically locked. Use the knob or operation screen to select the sterilization method, and download the recipe to the PLC. After checking, start the sterilization program, and the whole process will automatically follow the sterilization recipe.

Equip the spiral-tube heat exchanger for the sterilization retort and at the heating and cooling stages, process water in the retort passes through the shell side, while steam and cooling water pass through the tube side, so that the sterilized product will not directly contact the steam and cooling water to realize aseptic heating and cooling.

Throughout the whole process, the pressure inside the retort is controlled by the program by feeding or discharging compressed air through the automatic valve to the retort.

When the sterilization process is finished, an alarm signal will be issued. At this time, the door can be opened and unloaded. The triple safety interlock ensures that the retort door will not be opened when there is pressure in the retort, thus ensuring safe operation.

The uniformity of temperature distribution in the retort is +/-0.5℃, and the pressure is controlled at 0.05Bar.

Advantage of the pilot retort

Accurate temperature control, excellent heat distribution

The temperature control module (D-TOP system) developed by DTS has up to 12 stages of temperature control, and the step or linearity can be selected according to different product and process recipe heating modes, so that the repeatability and stability between batches of products are maximized well, the temperature can be controlled within ±0.5℃.

The pressure control module (D-TOP system) developed by DTS continuously adjusts the pressure throughout the whole process to adapt the internal pressure changes of the product packaging, so that the degree of deformation of the product packaging is minimized, regardless of the rigid container of tin cans, aluminum cans or plastic bottles, plastic boxes or flexible containers can be easily satisfied, and the pressure can be controlled within ±0.05Bar.

Highly clean product packaging

The heat exchanger is used for indirect heating and cooling for the water spray type, so that the steam and cooling water are not in contact with the process water. The impurities in the steam and cooling water will not be brought to the sterilization retort, which avoids the secondary pollution of the product and does not require water treatment chemicals (No need to add chlorine), and the service life of the heat exchanger is also greatly extended.

Compliant with FDA/USDA certificate

DTS has experienced thermal verification experts and is a member of IFTPS in the United States. It fully cooperates with FDA-approved third-party thermal verification agencies. The experience of many North American customers has made DTS familiar with FDA/USDA regulatory requirements and cutting-edge sterilization technology.

Energy saving and environmental protection

> The self-made high-quality spiral wound heat exchanger has high heat exchange efficiency and saves energy.

> A small amount of process water is quickly circulated to quickly reach the predetermined sterilization temperature.

>Low noise, create a quiet and comfortable working environment.

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for 2020 High quality Steam Pilot Retort - Pilot Retort – Dingtaisheng, The product will supply to all over the world, such as: Qatar, Johannesburg, Argentina, Our professional engineering group will always be ready to serve you for consultation and feedback. We are able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to give you the ideal service and goods. For anyone who is thinking about our company and merchandise, please contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We'll always welcome guests from all over the world to our business to build company relations with us. Please feel free to get in touch with us for business and we believe we are going to share the top trading practical experience with all our merchants.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.