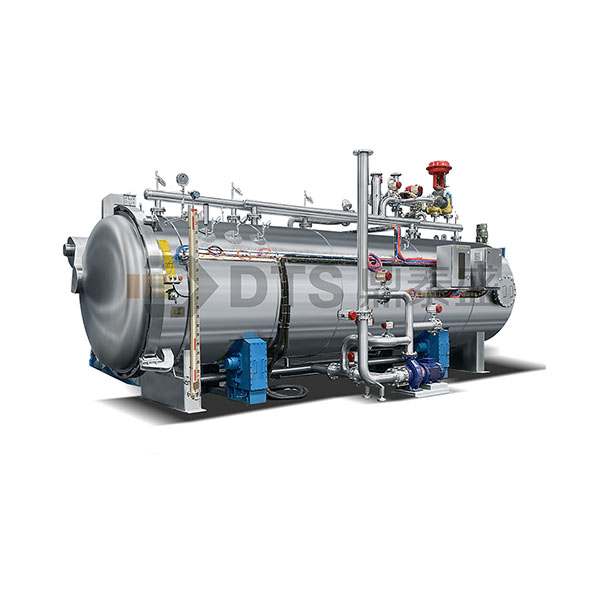

2020 Good Quality Double Layer Rotary Retort - Water Immersion And Rotary Retort – Dingtaisheng

2020 Good Quality Double Layer Rotary Retort - Water Immersion And Rotary Retort – Dingtaisheng Detail:

Working principle

Put the product into the sterilization retort, cylinders are individually compressed and close the door. The retort door is secured by triple safety interlocking. Throughout the whole process, the door is mechanically locked.

The sterilization process is automatically carried out according to the recipe input to the micro-processing controller PLC.

At the beginning, the high-temperature water from the hot water tank is injected into the retort vessel. After the hot water is mixed with the product, it is circulated continuously through the large-flow water pump and the scientifically distributed water distribution pipe. Steam is injected through the water vapor mixer to make the product continue to heat up and sterilize.

The liquid flow switching device for retort vessel achieves uniform flow at any position in vertical and horizontal directions by switching the flow direction in the vessel, so as to achieve excellent heat distribution.

In the whole process, pressure inside the retort vessel is controlled by the program to inject or discharge air through the automatic valves to the vessel. Since it’s water immersion sterilization, pressure inside the vessel is not affected by temperature, and pressure can be set according to different packaging of different products, making the system more widely applicable(3 piece can, 2 piece can, flexible packages, plastic packages etc.).

In the cooling step, hot water recovery and replacement can be selected to recover the sterilized hot water to the hot water tank, thus saving heat energy.

When the process is completed, an alarm signal will be issued. Open the door and unload, then prepare for the next batch.

The uniformity of temperature distribution in the vessel is ±0.5℃, and pressure is controlled at 0.05 Bar.

During the whole process, the rotation speed and time of the rotating body are determined by the sterilization process of the product.

Advantage

Uniform water flow distribution

By switching the water flow direction in the retort vessel, uniform water flow is achieved at any position in the vertical and horizontal directions. An ideal system for dispersing water to the center of each product tray to achieve uniform sterilization without dead ends.

High temperature short time treatment:

High temperature short time sterilization can be performed by heating hot water in a hot water tank in advance and heating from high temperature to sterilize.

Suitable for easily deformed containers

Because water has buoyancy, it can form a very good protective effect on the container when rotate.

Suitable for handling large packaging canned food

It is difficult to heat and sterilize the central part of large canned food in a short time by using a stationary retort, especially for food with high viscosity.

By rotating, the high viscosity food can be evenly heated to the center in a short time, and achieve effective sterilization effect. The buoyancy of the water at high temperature also plays a role in protecting the product packaging during the rotating process.

The rotating system has a simple structure and stable performance

> The rotating body structure is processed and formed at a time, and then balanced treatment is performed to ensure the stability of the rotation

> The roller system uses an external mechanism as a whole for processing. The structure is simple, easy to maintain, and greatly extend the service life.

> The pressing system adopts double-way cylinders to automatically divide and compact, and the guide structure is stressed to prolong the service life of the cylinder.

Package type

| Plastic bottles, cups | Big size softener bag |

Adaptation field

> Dairy products

> Ready-to-eat meals, Porridge

> Vegetables and fruits

> Pet food

Product detail pictures:

Related Product Guide:

We also supply merchandise sourcing and flight consolidation companies. We now have our very own manufacturing facility and sourcing business. We could present you with almost every kind of product relevant to our solution array for 2020 Good Quality Double Layer Rotary Retort - Water Immersion And Rotary Retort – Dingtaisheng, The product will supply to all over the world, such as: Florida, Greece, Lithuania, They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a should for you of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we are going to possess a vibrant prospect and to be distributed all over the world within the years to come.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!